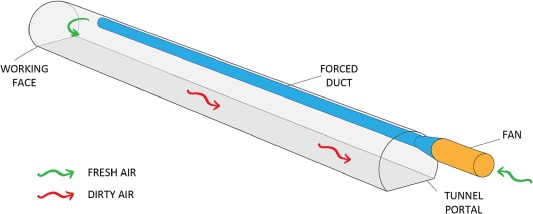

Ventilation systems are required during the construction of tunnels and mining roadways to provide a safe environment for workers and dilute the blasting fumes and combustion gases from diesel equipment. In addition, according to the international regulations, a minimal air speed in the underground infrastructure must also be guaranteed. The schematic diagram of a typical auxiliary ventilation system of dead-end tunnels and mining roadways is shown in Fig. 1.

Fig. 1. Schematic diagram of a typical auxiliary ventilation system of dead-end tunnels and mining roadways.

The ducting system and auxiliary fan must be sized to ensure the required airflow to the working face. However, to design the ducting system, the size of the tunnel and mobile equipment must be considered to allow sufficient clearance between the vent duct and mobile equipment. The axial fans are located at the tunnel portal to avoid the re-circulation of dirty air in the ventilation circuit. The power of the fans depends on the total pressure and the delivered airflow. Forced ventilation modes with leaky flexible ducts are generally used to supply fresh air directly to the working face in dead-end tunnels. The dirty air returns towards the tunnel portal through the tunnel section.

We are the top manufacturer brand in flexible and semi-rigid PVC ducting for mine and tunnel ventilation from China.PVC flexible air duct hose is made by PVC heavy duty mesh tarpaulin , Steel wire is frame retardant, if the diameter of duct is large, the diameter of steel wire will be large as well.The connect link of duct is rubber stripe.We can provide OEM upon the MOQ 2000 square meters.There is no requirment for quantity of our standard flexible ducts

Product

Lay Flat Ventilation duct

Spiral Ventilation Duct

Tunnel Ventilation Duct

Mine Ventilation Duct

PVC Coated Fabric

PVC /EVA Waterproofing Membrane

Feature

High-quality

Freight savings

High-performance

Safety

Environmental protection

Cost savings

Flame resistance

Anti -static